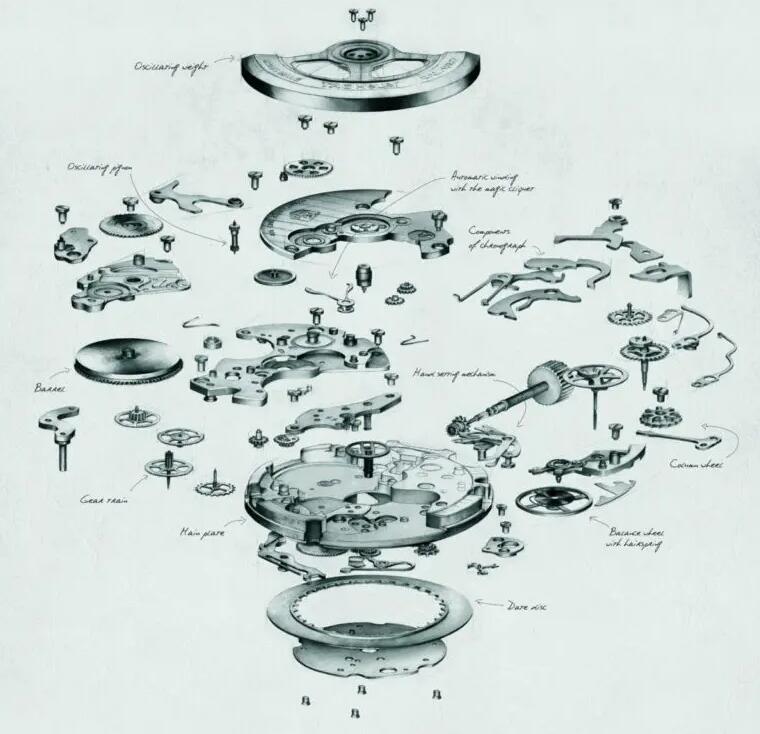

Tag Heuer Replica has been in an investment mood for several years now – at least when it comes to technical developments. With the Heuer 02, for example, the Swiss watch manufacturer entered the Olympus of manufacturers in 2017 with a specially developed mechanical movement. The Heuer 02 is – how could it be otherwise given the history of the manufacturer – a chronograph caliber with automatic winding and an integral part of model series such as the Carrera or Autavia.

But TAG Heuer is going one step further: In the TAG Heuer Research Institute, founded in 2018, various research projects are being driven forward under the leadership of Guy Sémon, who started at TAG Heuer as R&D Manager in 2004. One exciting development by Guy and his team is, for example, a hairspring made of carbon composite material, which, however, still faces some challenges on the production side – more on this in a moment.

TAG Heuer: Competition and dependence on the Swatch Group (ETA, Nivarox, silicon hairspring)

The hairspring, together with the balance wheel, forms the heart of every mechanical watch. The hairspring has a very important task, namely to “push” the balance wheel back to its starting position after each tick at a constant frequency. Together, the hairspring and balance wheel form the regulating, timing organ for the entire mechanism. In short: without a hairspring, there is no mechanical watch!

Carbon spiral springs: advantages and insights into production at TAG Heuer, La Chaux-de-Fonds

The carbon spiral springs were developed by the TAG Heuer Research Institute, which has been located within the main building in La Chaux-de-Fonds since 2018 and is the dream of the Sheldon Coopers of this world: A total of 25 employees are divided into three teams for the areas of solid-state physics, nanoparticle physics and advanced mechanics. The laboratory is equipped with all kinds of state-of-the-art technology such as transmission electron microscopes and alpha-proton spectrometers.

The production of the extremely delicate spiral springs is quite difficult, and TAG Heuer has developed a new production technology in connection with the use of carbon as a material. So-called wafers play a crucial role in the production process. You have probably heard of wafers in connection with the semiconductor industry: circuits are etched onto a wafer, which are then cut to size and soldered into chips. These chips then end up in televisions, smartphones, etc.

The carbon hairspring made its debut in TAG Heuer’s in-house caliber Heuer 02T, which in turn was installed in the limited edition TAG Heuer Carrera Tourbillon Nanograph model. With a RRP of over €20,000, however, the model is anything but cheap.

However, as has now become clear in an interview by Guy Semon with the TAG Heuer magazine Calibre11, there are problems in series production: the carbon hairspring is apparently not as easy to incorporate into a standard caliber such as the Sellita SW200 as hoped. Therefore, the TAG Heuer Autavia three-hand variant will be relaunched in early 2020 – but without a carbon hairspring.

TAG Heuer clearly still has a long way to go to get mass production of (cheaper) standard calibers with carbon hairsprings underway. Production is complex and the costs are high. The Swatch Group is currently much further ahead in this respect: since 2017, silicon hairsprings, which have similar advantages to carbon hairsprings, have been used in the Powermatic 80 automatic movement and thus in models from Tissot, Mido & Co., which are available from around €700 (for example Tissot Seastar 1000).